Unlocking Success: Discover the Power of Contract Manufacturing for Your Business

In today's competitive landscape, businesses are constantly seeking innovative ways to streamline operations and enhance profitability. One of the most effective strategies to achieve this is through contract manufacturing. By partnering with specialized manufacturers, companies can tap into a wealth of expertise and resources, allowing them to focus on their core competencies while leaving the intricacies of production to seasoned professionals.

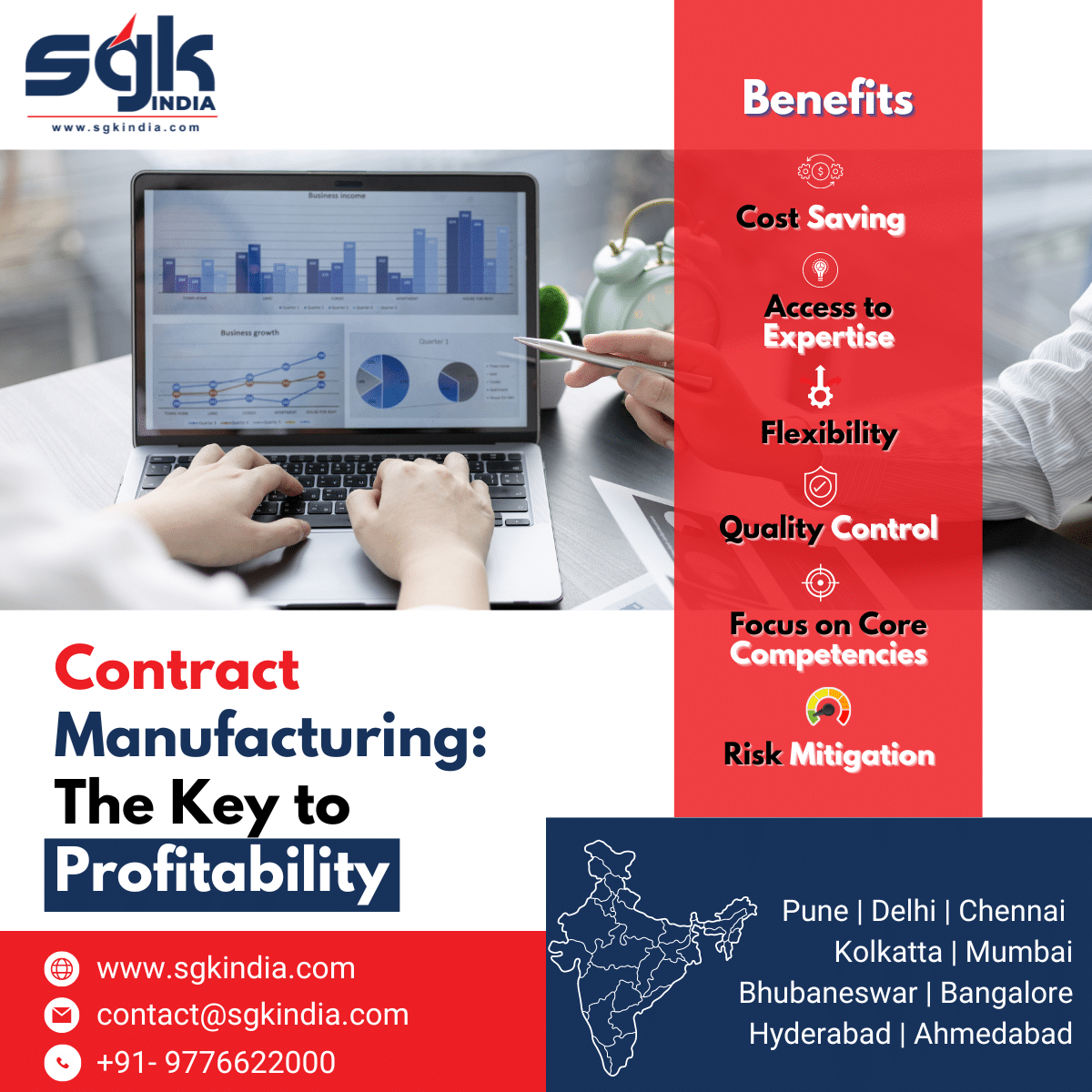

The benefits of contract manufacturing are extensive, ranging from cost savings to increased flexibility. In an era where market demands can shift rapidly, having the ability to scale production without the burden of heavy investment in facilities and equipment can be a game changer. This approach not only optimizes resources but also propels businesses toward greater efficiency and adaptability, setting the stage for lasting success.

What is Contract Manufacturing?

Contract manufacturing is a business practice where a company hires a third-party manufacturer to produce goods or components on its behalf. This arrangement allows companies to focus on their core competencies, such as product design, marketing, and sales, while outsourcing the manufacturing process. By partnering with a specialized manufacturer, businesses can leverage advanced technologies and expertise that may not be available in-house.

This approach is increasingly popular across various industries, including electronics, pharmaceuticals, and consumer goods. Companies can access high-quality production capabilities without the significant capital investment required to build and maintain their own manufacturing facilities. Contract manufacturers often have established supply chains and industry knowledge, which can lead to reduced costs and shorter time-to-market for new products.

Overall, contract manufacturing provides flexibility and scalability, enabling businesses to respond quickly to changing market demands. By collaborating with manufacturing partners, companies can adapt their production volumes, optimize resource allocation, and ultimately enhance their operational efficiency.

Benefits of Contract Manufacturing

One of the primary benefits of contract manufacturing is cost efficiency. Companies can significantly reduce expenses by outsourcing production to specialized manufacturers. These partners often have established processes, economies of scale, and access to advanced technology, allowing them to produce goods at a lower cost than in-house production. This reduction in overhead enables businesses to allocate resources more effectively, focusing on core operations like marketing and sales.

Another key advantage is increased flexibility and scalability. Contract manufacturing allows businesses to meet fluctuating demands without the need for substantial investments in facilities or equipment. Companies can quickly adjust production levels based on market trends or seasonal variations, ensuring they remain competitive. This adaptability is particularly beneficial for startups and small enterprises that may lack the capital for large-scale manufacturing.

Lastly, partnering with a contract manufacturer provides access to specialized expertise and improved quality control. These manufacturers often possess extensive industry knowledge and experience, resulting in high-quality products. By leveraging their skills, businesses can enhance their offerings and reduce the risk of production errors. This collaboration can lead to innovation, faster time to market, and ultimately, greater customer satisfaction.

Choosing the Right Contract Manufacturer

Finding the right contract manufacturer is crucial for your business success. Begin by identifying your specific needs, including production volume, timelines, and quality standards. Research potential manufacturers and consider their experience in your industry, as well as their ability to scale with your business as it grows. Look for manufacturers that specialize in your product type to ensure they have the necessary expertise and equipment.

Once you have a shortlist of candidates, evaluate their production capabilities and facilities. Request site visits, if possible, to assess their operations firsthand. Pay attention to their quality control processes and certifications, as these are indicators of their commitment to producing high-quality products. Additionally, consider their geographic location; a manufacturer closer to your business can reduce shipping costs and lead times.

Communication is another critical factor when choosing a contract manufacturer. Establish a clear line of communication from the outset and ensure that they are responsive to your inquiries. A good partnership relies on transparency and collaboration, so choose a manufacturer that values your input and is willing to work closely with you to meet your goals. Prioritize building a relationship that fosters trust and ensures both parties are aligned on expectations and deliverables.